UNSTABLE ROCK AND ITS TREATMENT SNOWY MOUNTAINS SCHEME

Fig. 11—Mortar being applied pneumatically over light wire mesh.

Reinforcement of pneumatically applied mortar.

Where mortar is used over wide areas of weak rock it is reinforced with mesh. The type of reinforcement used has varied slightly in different tunnels. The general aim is to use mesh which is flexible enough to be moulded to follow closely the rock contours and with openings large enough to minimize wastage of mortar rebounding from the wires.

In Eucumbene-Snowy and Snowy-Geehi tunnels light mesh in the form of 17 gauge wire netting with 1 ½ in. openings and “heavy” mesh in the form of 8 or 10 gauge chain-wire netting with 2-in. openings have been used. Recent practice is to use heavy mesh almost exclusively. The mesh is fastened either directly to the rock or to the initial layer of mortar with surface anchors so that it fits firmly and snugly to the surface.

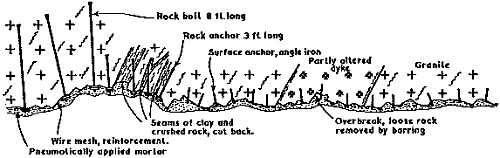

Surface anchors penetrate the rock to a depth of less than one ft and include nails, staples and embedded wire ties. Depending on the character of the rock treated, surface anchors are supplemented by rock anchors consisting of 5/3 in. diameter bolts 1 to 3 ft long, embedded in the rock, and by standard grouted rock bolts usually 8 ft long (Fig. 12).

Fig. 12.—Support and final treatment of a large area of weak rock of varying quality.

Application of pneumatically applied mortar over wet rock.

The mortar after setting adheres strongly to wet rock. Problems arise where ground water flows freely out of the rock and down the rock face washing away the mortar before it can set. Under these conditions it is necessary first to control the flow by locating its source and concentrating the flow in short tubes or pipes attached to the rock by quick-setting mortar or set in holes specially drilled to intercept the flows.

Determination of final treatment of unlined tunnels

Blasting and excavation of broken rock causes the rock surfaces in the walls and roof to become coated with a layer of rock dust which obscures many details of the rock including details of joints and seams. Under these conditions it is very difficult to assess reliably the treatment the rock requires. Commencing with the Tooma-Tumut Tunnel it has become the practice to wash thoroughly the rock in unlined tunnels before detailed geological mapping and inspection for determination of final treatment.