Engineering Geology for the Snowy Mountains Scheme

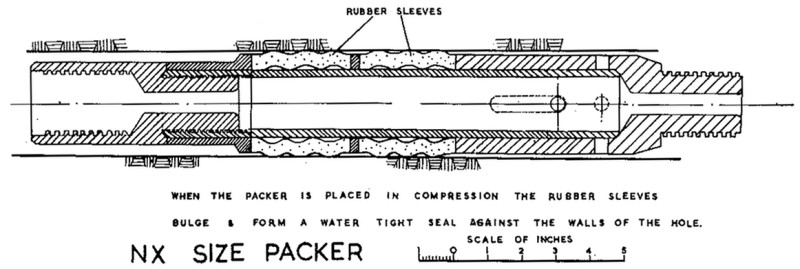

Fig. 6.—Packer for Water Pressure Testing

Electric Logging—Drill holes are logged after drilling has been completed by means of a single-electrode electric logger. An electrode is lowered down the hole and a recording instrument at the surface plots two curves showing changes in the electrical resistivity of the rock forming the walls of the hole, and changes of self potential, respectively, against depth, on a scale of 1 inch : 10 feet. Use of this method of drill hole logging was prompted by the example of the petroleum industry, where it is now common practice to make electric logs as well as gamma-ray and neutron logs, of holes put down for petroleum. The methods are described in many publications (Ref. 4). As used in the Snowy Mountains, electric logging can be applied only to uncased sections of the drill hole full of water. It is very rapid. Several hundreds of feet can be logged in less than an hour.

Fresh solid granite possesses high resistivity. Considerably lower resistivity is shown by weathered granite, crushed granite such as occurs along faults, clay seams, and closely jointed zones.

Where these occur in otherwise fresh solid granite they show up in the electrical resistivity curve as deflections towards the low resistivity side of the graph (Fig. 7). Other hard rocks behave similarly. Thus the electrical resistivity log can indicate the presence of weak zones and defects.

The greatest value of electric logging is in holes where drill core has been lost, where it provides a basis for judging the reasons for the core losses. Logging of holes with high or complete core recovery is worth while since this provides experience for interpreting electric logs of holes where core has been lost.

The satisfactory interpretation of the self-potential logs has not yet been achieved. These logs show the potentials of natural earth currents.

Water-pressure testing and electrical logging provide in- dependent sets of data concerning the rock penetrated by the drill hole.