Discussion at Technical Session No. 9—Rock Mechanics

The actual conditions met underground would involve drilling under load and thus be relatively difficult to reproduce, so in the first instance a simpler experiment has been tried which should be subject to much the same uncertainties. In this a slot is cut in the block and the jack cemented in; the whole is then put in the testing machine and the jack pressure raised at the same time as the load in such a way that the deflection between two measuring pins across the jack is equal to the average deflection of all measuring pins outside the jack. Some of the measuring pins were inset in drill holes in the rock and others were subsequently affixed to the surface with araldite. In the present experiments measurements on these two sets were quite consistent, and the pins set in drill holes showed negligible tilt; however, it should be said that in another series of experiments with a jack at greater depth very considerable tilting of the pins did occur. The inset in Fig. 9c shows a plan view of the rock with the position of the jack shown dotted; the measuring points are in pairs 3 in. above and 3 in. below the plane of the jack, those at B being across the jack and A, C, D, E outside it. Curve 1 in Fig. 9b shows the results for marble obtained in this way: they are seen to lie extraordinarily well on a straight line, the jack pressure being consistently about 12 per cent greater than the load stress. This may be regarded as an experimental determination of the edge effects for a jack in a relatively small block and is of the same order as the theoretical calculations of the S.M.A. workers.

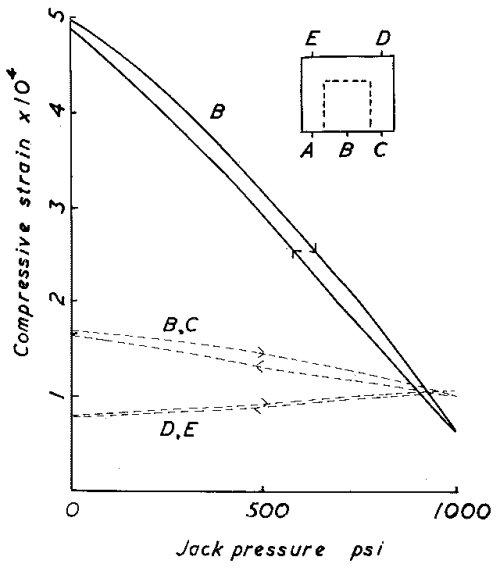

At any stage the jack pressure can be varied cyclically at constant load stress and Fig. 9c shows such an experimént for marble at a load stress of 785 p.s.i. The two measuring points, A, C, on the face containing the jack move in a different manner to those, D, E, on the opposite face but it appears that all agree at a cancellation pressure of about 900 p.s.i. This can be repeated over several cycles but the degree of correspondence of the various curves suggests that cancellation pressures cannot be obtained to better than the nearest 50 to 100 p.s.i.

In principle, Young’s modulus may be measured in situ by slot-cutting or the use of a flat jack. For example, it appears from Fig. 9c that reducing the jack pressure from 900 p.s.i. to zero causes an increase in compressive strain between the measuring pins B across the jack of approximately 3.8 × 10-4 and using these values in Alexander’s formula for wj with μ = 0.2 gives E : 7.4 × 106. On the other hand, the uniform strain of 1.1 × 10-4 in the block at the cancellation pressure for the load stress of 785 p.s.i. gives a measure of Young’s modulus which is E = 7.2 × 106. These results are admittedly very crude, but they suggest that flat jack measurements should give a reliable measurement of Young’s modulus in sound, uniformly stressed rock.

Fig. 9c.—Strain in a Marble Block with a Compressive Stress of 785 p.s.i. and Various Jack Pressures.

Inset is a plan view of the block showing the position of the jack (dotted) and the measuring points. The full curve shows the variation with jack pressure of the strain between the measuring points at B; the dotted curves show the same quantity for the points D and E (average) and B and C.