Field and Laboratory Tests in Rock Mechanics by L. G. Alexander

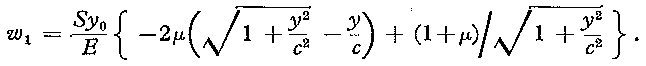

(b) For a slot of finite width, 2y0, regarded as an elongated ellipse, a correction term w1, is to be added to the above result, where,

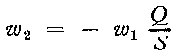

(c) The above slot of small finite width is subject to interference from the stress field Q, at right angles to the field being measured. The additional contraction is:

Thus the two correction terms oppose each other and cancel when the stress fields are equal.

Graphs of w0, w1, w2 are given in Fig. 8 for a slot of length 13 in. and width 1.8 in. The displacement caused by the raising of jack pressure is taken as that due to an infinitely thin slot of the length of the jack. This is denoted by wj and is the value assumed by w0 for 2c = 12 in. with S = P, the jack pressure.

At cancellation

wj = w0 + w1 + w2.

Evaluations for the above dimensions, for pin distances y = 3 and 5 in. from the centre of the slot, gives:

S = 0.85 P + 0.07 Q, for y = 3,

S = 0.83 P + 0.07 Q, for y = 5,

where P is the cancellation jack pressure.

The factors are graphed for different lengths of slot.

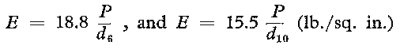

For calculation of the Young’s modulus we take the jack test curve, and apply the theoretical value for wj. We find

for the moduli calculated from the displacements (d6, d10) of the 6- and 10-in. pins respectively, corresponding to a pressure change P in the jack. (The above theory may require modification to allow for the probable cracking of the grout between the ends of the jack and the slot.)

Typical Results:

A typical test curve is shown in Fig. 9, which is the mean taken from a number of tests. Some features are:

- Continued deformation after the slot is cut, prior to the jack test, is clearly associated with site jointing, and is notably absent on some sites.

- On sites with few joints, the jack test curve is nearly linear, with very little weep or permanent deformation. On close-jointed faces, the curve shows more of the characteristics of the plate bearing test curve.

- Cancellation pressures for the pins furthest from the slot are on the average lower than for the pins close to the slot, The average difference is about 9%.

- Young’s modulus calculated for the pins furthest from the slot is on the average higher than that for those closer to the slot. The difference averages about 10%. Both (c) and (d) may be associated with the continued deformation after slot cutting. This may be not fully cancelled when the jack pressure is applied, and relatively greater on the 6-in. pins.

- Repeated test cycles give no significant change to the cancellation pressure or permanent deformation.