Engineering Geology for the Snowy Mountains Scheme

They contain an undesirably high proportion of weathered granite particles, sedimentary rocks of platy shapes, coated particles, and often a small proportion of cherts which are potentially reactive with cement alkalies. For these reasons the aggregates are regarded as unsuitable for use in important concrete structures.

Thick beds of sands interbedded with clay, lignite and gravel occur around the edges of and beneath the Tertiary basalts in the Kiandra-Cabramurra region, capping ground high above the present valleys. Some of these ancient alluvial deposits around the edges of the basalt have been worked for gold. The sands are of good quality, being composed almost entirely of quartz grains. They usually contain an excess of fine sizes, but otherwise their grading is good. Their chief disadvantages as sources of concrete sand are the large quantity of overburden of basaltic soil and boulders which must be stripped from them, and the processing required to remove excess fines.

Various rock types have been examined in regard to their suitability for crushing to produce coarse and fine aggregates.

At first the basalt was considered to be very promising, particularly as a site could have been found where removal of the basalt would have exposed suitable natural sands below. However, it was discovered that a considerable amount of basalt which was perfectly fresh and apparently sound when first recovered as diamond drill cores or exposed in quarries, later developed a network of fine intersecting deep-seated cracks, and disintegrated. The affected basalts also developed light grey spots prior to cracking. The suitability of these basalts for concrete aggregates is questionable.

Various kinds of granite rocks have been examined and tested. A common disadvantage is that they frequently are very rich in mica, which is released by crushing in the sand sizes in the form of thin flexible sheets.

However, concrete of satisfactory strength and durability made with both coarse and fine aggregates crushed from biotite- rich granite was used for the construction of Guthega Dam and the lining of Guthega Tunnel. The fine aggregate contained up to 20 per cent. by weight of free biotite mica. This granite was obtained partly from tunnel spoil and partly from a surface quarry.

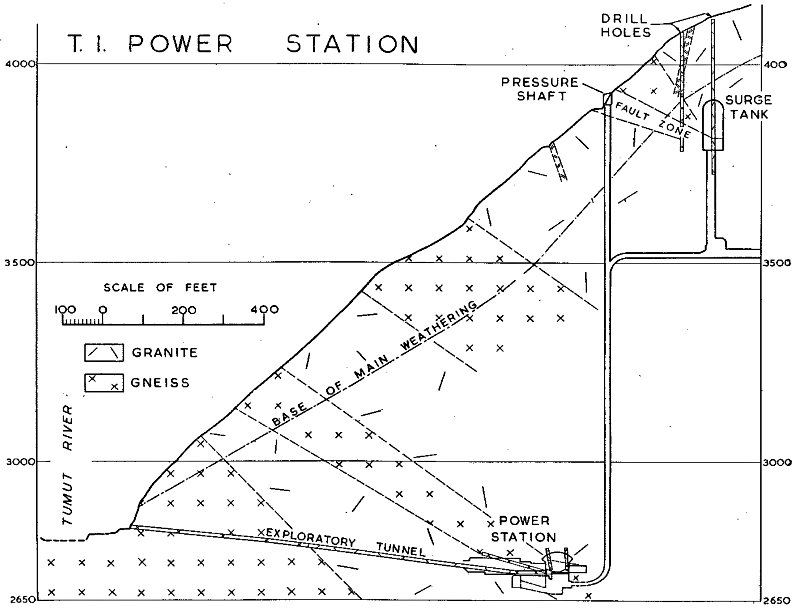

Granite and granitic gneiss were tested and found to be satisfactory for coarse aggregate for use on T.1 Project. However, most of the aggregate to be used on this project is to be obtained by crushing diorite from a site at Happy Jack. This produces both coarse and fine aggregate of very good quality.