Engineering Geology for the Snowy Mountains Scheme

Siting of Drill Holes.—The position of each drill site is marked out on the ground by the engineering geologist, taking into account details of the local geology. Inclined holes are very frequently used, sloped in directions designed to obtain as much geological information as possible compatible with reaching the engineering targets set for the drilling. For example, in the case of sedimentary and metamorphic rocks, the hole would be directed as nearly as possible at right angles to the bedding of the strata, or as nearly as possible at right angles to the main joint systems in rock like granite. At dam sites sloped holes are almost always drilled to pass, at as shallow a depth as possible, under the river bed, since river beds are usually to a greater or less extent covered by gravel and are inaccessible due to the water, and there is always a probability that the course of the river is following a weak zone in the rock.

Drilling Equipment.—Diamond drills with hydraulic feed are used almost exclusively in preference to drills with screw-feed. With hydraulic feed, the driller can maintain close control over the pressure of the drill bit on the material being drilled, resulting in better core recoveries and also more information obtainable by the driller himself.

The largest standard-size bits are used, since core losses due to blocking, breaking and grinding of the core in the core barrel increase as the size of the core is decreased.

The NX-size bit, which produces a core about 2 inches in diameter was chiefly used in conjunction with double-tube core barrels, until the introduction of the NM core-barrels and bits about a year ago;

the adoption of NM core barrels is regarded as a most important advance in drilling technique, since it leads to core recovery much superior to that obtained with all other coring equipment hitherto used.

It consists of a double tube core barrel, in which the inner tube is of the type which is mounted at the top on bearings enabling it to remain stationary while the outer barrel carrying the diamond cutting bit is rotated. The lower end of the inner tube extends no Within about 1 inch of the cutting face of bit; and the core-lifter, by means of which the core is broken off and retained in the barrel, is located in the lower end of the inner-tube. The drilling water passes down between the inner tube and the outer barrel and emerges through holes in the face of the bit. The core, therefore, passes immediately up into the protecting inner tube without being affected by the drilling water.

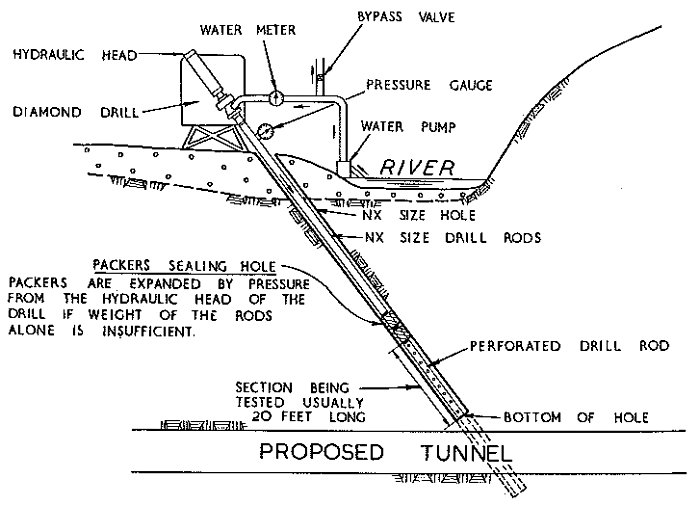

Fig. 5.—Water Pressure Testing of Diamond Drill Holes.