Field and Laboratory Tests in Rock Mechanics by L. G. Alexander

For analysis, four sites for measurements in each of the three directions (vertical, horizontal transverse to the tunnel, horizontal along the tunnel) are tested and average stresses in each direction are obtained from the results. The sites are selected as far as possible near the crown line of a roof, or spring line of a wall in order to permit analysis in terms of horizontal and vertical primary rock pressures (stresses in these positions are not influenced by the primary shear stress). The sites are as flat as possible, in areas that line up with the general excavation, and not adjacent to pronounced irregularities. Tight jointing across a face is generally present, but main joint planes are avoided. The sites selected must be in sound rock. The test adopted for soundness is to strike the rock with a 3 to 5 ft. length of steel rod (1⅜ in. drill steel). This has been found to give differences in tone not detectable with lighter bars or hammers. A site with any trace of drumminess is rejected.

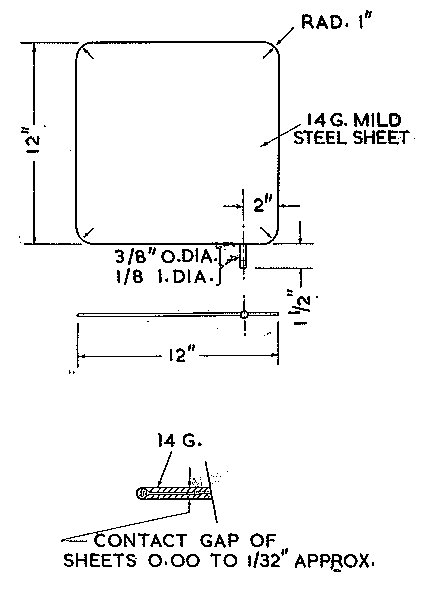

Fig. 4.—Stress Test Slot.

In the granitic rocks where these tests have been done, the slots have been cut by diamond drilling a row of overlapping holes (Fig. 4). The bit of the drill is guided by a steel template of the same shape as the cross section of the finished slot.

The Freysinnet jack, as used by Tincelin (which has a tubular rim designed for large displacements), has been replaced by a thin flat jack (Fig. 5), whilst the measuring pins, which Tincelin disposed for strain measurement on the rock faces, are placed here for measurements of contraction across the slot (Figs. 6, 9). Three pairs of pins give three independent determinations of stress for the site. The restriction to measurements across the slot, which are of the average order of 0.010 in., permits the use of a removable extensometer. This permits long-term observations of creep or of changes in stress caused by progress of the excavation in which the sites are located.

Fig. 5.—Flat Jack. Edge weld third size.